Greenfield Energy

TomCo's 100% owned subsidiary working to establish near term oil production in Utah

Greenfield Project Structure Aligned with Investors

- TomCo has operational control over the project (100 % working interest)

- Project restructured to align stakeholder interests with investors

Project development underway

The Greenfield Energy Project

In August 2021 TomCo announced an agreement with it’s Joint Venture partner, Valkor LLC to acquire Valkor’s half of Greenfield. TomCo currently owns 100% of Greenfield, though this may change as we move forward with Valkor to develop the opportunities available at Vernal.

The Greenfield oil sand remediation plant is located to the Northwest of Vernal Utah.

- The site in receipt of a full mining permit

- Utilities infrastructure are all in place

- Minable resources with an average strip ratio of 2:1

- Significant reserves and economic returns confirmed by CPR (CPR published 1Q 2022)

- Further 55m barrels of oil in place available for in-situ recovery; CPR pending finalisation of development assessment

TomCo’s wholly owned subsidiary, Greenfield Energy owned, until 2024, a 10% Membership Interest in Tar Sands Holdings II(TSHII). In 2024, TomCo sold that interest back to the vendor as part of a transaction by which the vendor would sell 100% to a named third party. That third party planned to refurbish the former refinery on site and had no interest in mining the oil sands. We have secured a right to negotiate a lease, on normal commercial terms, by which we could mine oil sands on those parts of the TSHII site that are not required for the re-started refinery. Progress in negotiating that new lease is held up pending progress being made with the proposed transaction.

TSHII owns approximately 760 acres of land in Uintah County, Utah, USA. Subject to securing the requisite funding and the above new lease, Greenfield plans to use the Site, for the future mining of oil sands and construction of a commercial scale processing plant utilising the findings of the FEED study, which covers the production facilities for a 5,000 barrels of oil per day, and other knowledge and experience gained from Greenfield’s operation of the test plant. The Site has existing infrastructure, plant and equipment, together with an existing Large Mine Permit No. M0470032, that could facilitate any future development by Greenfield.

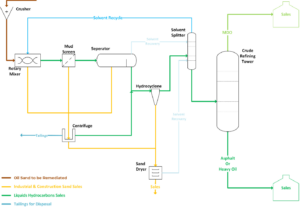

The main method for separating oil from oil sands involves using large gravity separation tanks to produce diluted bitumen, which can then be sent for refining. Issues with this method of separation include 1) large capex requirement, 2) very large requirement for water, 3) dirty (oiled) sand to be disposed of, and 4) bitumen output that contains high levels of sulphur.

The Greenfield project aims to use an innovative separation technology that gets around some of the problems with the “traditional” process.

This process has a number of advantages over conventional oil sands separation techniques:

- A modular, scalable extraction plant

- Lower start-up capex

- Lower water requirement

- By-product of clean sand, requiring no expensive remediation

- Output of sweet (low sulphur) heavy oil, with no further refining

The following diagram illustrates the process.

To view a presentation on the Greenfield site please click here.

Greenfield benefits from 6 revenue streams:

- Fracking & Well Sand

- Silica

- Industrial Sand

- Building Sand

- Asphalt/Heavy Oil†

- Middle Distillate Oil (MDO)

AC Oil

AC Oil is a 100% subsidiary of Greenfield and has permits, secured with the participation of our partners Valkor, for the drilling of “conventional” holes to extract in-situ oil. AC Oil has a lease or this purpose over part of the Site at TSHII. That lease is not affected by Greenfield’s 2024 disposal of its previous 10% ownership stake in the TSHII lands. Valkor is drilling on neighbouring lands and we are working towards an arrangement that would extend those operations to the AC Oil lease.